Learn More About Fourslide Stamping

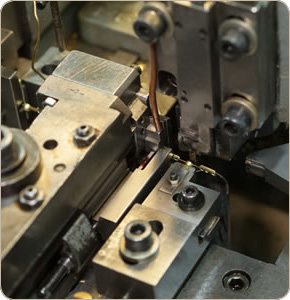

The fourslide stamping (or four slide stamping) process is a method of forming wire and coiled strip stock into intricate parts by using a press and forming slides coupled together in the same machine. Although fourslide has been around since the middle 1800’s, it and its capabilities are not as well-known as those of progressive die stamping.

Case Study: A Ten Step Process Reduced to Three!

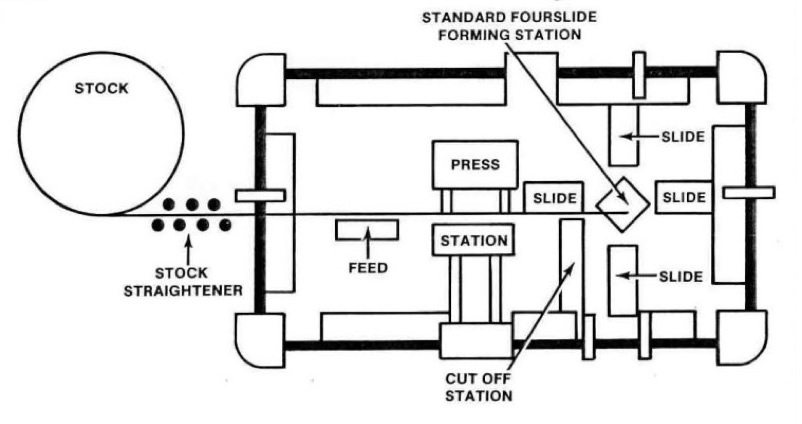

This machine should be used for parts requiring forming in more than one plane and requiring more than one forming motion. A schematic of a typical fourslide with a press section is shown below. This can be used with both wire and strip stock where blanking, coining or preforming operations are called for in the part design. Some fourslides will include a press-head station instead of a full progressive-type die section, to accomplish limited preparatory functions on the raw stock.

The raw material is pulled from the reel by a feed mechanism, which then pushes it into the press station where all blanking, coining, or preforming operations are accomplished. Basic rules for blanking holes or slots should be 1 ½ times stock thickness. Narrow sections should also be 1 ½ times stock thickness, but lower ratios can be accomplished. Reducing the ratio will likely create a higher maintenance die, however.

Now in its preformed and blanked configuration, the material is pushed into the fourslide forming station where it is held to the king post and cut off from the raw stock strip. Once the lead piece is separated from the preformed parts, the various forming tools, mounted on four cam actuated slides, form the strip into the required shape in a sequence of precisely timed motions.

With the addition of auxiliary forming slides to the four standard slides in the forming station, almost any form can be achieved. In the forming area, an inside radius of a bend should not be less than the metal thickness. Even with this rule, a hard metal will sometimes crack in the forming or crack after a period of time in the field due to a fatigue point of a sharp bend. The larger a formed radius is, the easier it is to form and the more reliable it will be.

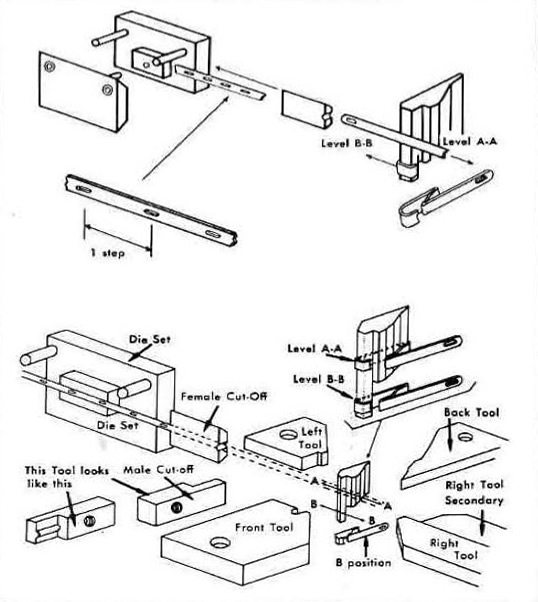

Here we can see a fairly complicated forming operation done in a fourslide that creates little scrap, as compared to progressive die stamping. Strip stock of the finished part width is fed into the press station which blanks out a hole. Then the strip is fed into the forming station where the part is formed using a two level forming operation in the king post timed with double forming strikes from some of the slides.

Here we can see a fairly complicated forming operation done in a fourslide that creates little scrap, as compared to progressive die stamping. Strip stock of the finished part width is fed into the press station which blanks out a hole. Then the strip is fed into the forming station where the part is formed using a two level forming operation in the king post timed with double forming strikes from some of the slides.

The advantages of drastically reduced scrap and complex forming at production speeds at a fraction of the tooling costs make fourslide a viable choice of manufacturing. Material selection remains wide open, as well.