Working with Copper

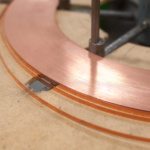

Copper and copper alloys are commonly used in many everyday products. Their attribute of being highly conductive makes them a very suitable option for electrical wires, cables, electric contacts, and other parts that require the ability to pass electrical currents through them. They also are thermal conductive which make them an ideal choice for automotive radiators, home heating appliances, heat exchangers, Solar applicators, and any other parts that require the conduction of heat. A bonus to these applications in which water or other liquid substances may be in contact with your stamped part is copper has an outstanding ability to withstand corrosion which is why it’s a top choice for pipes and valves. Copper can also be soldered and brazed as well as welded and buffed to most desired textures and lusters needed.

the ability to pass electrical currents through them. They also are thermal conductive which make them an ideal choice for automotive radiators, home heating appliances, heat exchangers, Solar applicators, and any other parts that require the conduction of heat. A bonus to these applications in which water or other liquid substances may be in contact with your stamped part is copper has an outstanding ability to withstand corrosion which is why it’s a top choice for pipes and valves. Copper can also be soldered and brazed as well as welded and buffed to most desired textures and lusters needed.

Copper is often added to other alloys to create new properties of the element to achieve a desired manufacturability effect in the material.

| Alloy | Copper is alloyed with | Uses |

|---|---|---|

| Brass | zinc | screws, wires, plumbing components, electrical connectors, musical instruments, door furniture, and ornaments |

| Bronze | tin | statues, bearings, electrical connectors, springs, clips |

| Phosphor bronze | tin, phosphorus | precision bearings, springs, cymbals, instrument strings |

| Aluminium bronze | tin, aluminium (iron, nickel, silicon) | tools, high-temperature aircraft, and automobile engine components |

| Cupronickel | nickel (iron, manganese) | coins, external components in marine environments |

| Nickel Silve | nickel, zinc | cutlery, keys, zips, coins, wind and ‘brass’ instruments, banjo fingerpicks |

Table Source: http://www.essentialchemicalindustry.org/metals/copper.html

Copper Conductivity

Copper may not be the most conductive metal on the market, it’s still usually the top choice for electrical components due to its strength, formability corrosion resistance and usually a cheaper option than pure silver, which is the only metal more conductive than copper.

| Material IACS (International Annealed Copper Standard) | ||

| Ranking | Metal | % Conductivity* |

| 1 | Silver (Pure) | 105% |

| 2 | Copper | 100% |

| 3 | Gold (Pure) | 70% |

| 4 | Aluminum | 61% |

| 5 | Brass | 28% |

| 6 | Zinc | 27% |

| 7 | Nickel | 22% |

| 8 | Iron (Pure) | 17% |

| 9 | Tin | 15% |

| 10 | Phosphor Bronze | 15% |

| 11 | Steel (Stainless included) | 3-15% |

| 12 | Lead (Pure) | 7% |

| 13 | Nickel Aluminum Bronze | 7% |

* Conductivity ratings are expressed as a relative measurement to copper. A 100% rating does not indicate no resistance.

Copper Strength/Formability

Copper is a relatively soft and malleable metal with excellent formability. Copper’s exceptional formability is most readily demonstrated by its use in such a wide variety of applications from highly technical electrical components to home fixtures and automobile parts.

If you’re looking for a metal that is malleable, fairly easy to machine, resistant to corrosion and high conductivity you may have found your material of choice.

Source: