Progressive Die Stamping

When progressive die stamping is determined to be the most efficient and appropriate manufacturing process for your component, GEMCO has the power press capability to form strip material from .004″ to .100″ thick and up to 8.00″ wide. To ensure a high degree of quality, progressive dies are designed, produced, and qualified in-house by GEMCO’s experienced craftsmen. Understanding the requirement for tight tolerance, precision metal parts and accurate repeatability, your tools are designed using AutoCAD and SOLIDWORKS and produced utilizing our wire EDM and CNC milling centers.

Supporting Your Competitive Edge

GEMCO understands your need to remain competitive in today’s global market. In response to this, GEMCO has incorporated Value-Added Services like in-die insertion of contacts, rivets and PEM™ Fasteners into the progressive die metal stamping process, saving time, labor, and money. Whether you require loose parts, reeled parts on a carrier, or specially handled and packaged parts, we will work with you to supply components in a configuration that best suits your assembly needs.

Materials for Function & Performance

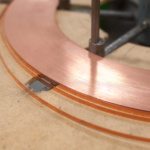

Selecting the right materials is critical to the success of your part. Offering you the expert advice you’re looking for, GEMCO’s experience with a vast array of materials makes your search for component sourcing a trouble-free experience. All of the copper-based materials, low and high carbon steel, 300 and 400 series stainless steel alloys, as well as aluminum, pre-plated and clad bi-metal strips are available.

Is Progressive Die Stamping right for your part?

Consider submitting your part drawing here. Once we see the design and the dimensions, we’ll contact you with our recommendations.