Fourslide Stamping

Fourslide/Multi-Slide tools are a cost-effective alternative to a progressive tool, especially when production requirements may not be significant enough to justify a substantial investment. These tools are capable of producing high quality, precision stampings and wire forms. Working in three planes, Fourslide/Multi-Slide machines are very versatile, which helps to overcome design constraints. The incorporation of a progressive die provides the ability to integrate special forms, features and identification markings. Less complex than a progressive die, first article submission is oftentimes faster.

While there are limitations, your parts may benefit from the cost saving advantages offered by the Fourslide/Multi-Slide process.

GEMCO’s ability to incorporate value added processes such as in-die insertion of electrical contacts, rivets and PEM™ Fasteners as well as tapping holes and designing two-stage tools to eliminate secondary operations offers additional cost saving opportunities.

How can fourslide stamping help you?

Please visit our Secondary Operations & Assemblies and Value-Added Services pages to learn how we can customize an assembly and consignment solution to meet your needs.

Materials for Function & Performance

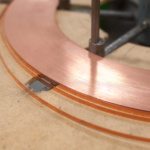

Selecting the right materials is critical to the success of your part. Offering you the expert advice you’re looking for, GEMCO’s experience with a vast array of materials makes your search for component sourcing a trouble-free experience. All of the copper-based materials, low and high carbon steel, 300 and 400 series stainless steel alloys, as well as aluminum, pre-plated and clad bi-metal strips are available.

Case Study: How GEMCO simplified a customer’s process by 50%

Is Fourslide Stamping Right for your Part?

Consider submitting your part drawing by clicking the button below. Once we see the design and the dimensions, we’ll contact you with our recommendation.